Whatsapp: +8615936220108

Email: info@hnjlzk.com

Whatsapp: +8615936220108

Email: info@hnjlzk.com

News

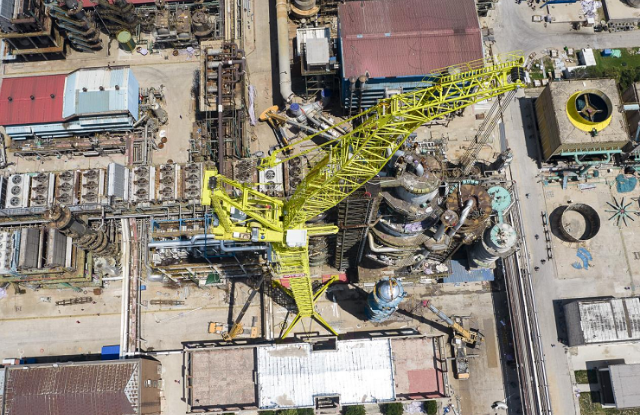

JLD2250S luffing tower crane, as the main crane of the project, carried out the replacement of catalytic cracking unit overhaul tanks in the petrochemical plant overhaul project.

The petrochemical plant site has small space, is close to the hoisting location, and has many maintenance hooks.

When the JLD2250S luffing tower crane is under the unattached condition,, its maximum independent tower height can reach 134m,maximum lifting height is 198.5m, maximum amplitude can reach 68.5m, and its maximum lifting capacity can reach 200t, which can meet the needs of large-amplitude, multi-point, small-amplitude, large-tonnage petrochemical maintenance work.

There are many pipe corridors in the petrochemical plant, and the height limit is usually 5m, and the cross-section size of JLD2250S transportation is controlled within 3.8m, and the transportation meets the height limit of 5m. The tower adopts self-elevating jacking plus section, can realize the narrow space assembly jacking, avoid like crawler crane large area occupying ground space for group pole, wrenching pole work space. Narrow site construction advantage is obvious, can be easily realized in a small space tower crane truck, group arm, lifting section and other work.

JLD2250S transportation is controlled within 3.8m, and the transportation meets the height limit of 5m. The tower adopts self-elevating jacking plus section, can realize the narrow space assembly jacking, avoid like crawler crane large area occupying ground space for group pole, wrenching pole work space.

Narrow site construction advantage is obvious, can be easily realized in a small space tower crane truck, group arm, lifting section and other work.

The advantages of tower cranes in petrochemical maintenance.

JLD2250S luffing tower crane has many advantages such as strong lifting capacity, small footprint, high efficiency, simple foundation treatment, convenient disassembling and assembling, low transportation cost and high safety.

Modularized advanced design concept ensures the convenient disassembly and assembly of JLD2250S Jib Tower.

The tower base, tower body, set frame jacking, standard section lifting, herringbone frame luffing, lifting arm and other modules are highly integrated, no disassembly and assembly within the module, and the connection parts between modules are equipped with special disassembly and dismantling tools, so that disassembly and dismantling efficiency is high, and the transfer cost is low.

Simple foundation treatment of the chassis type, no pressurized weight. The chassis adopts a unique support adjustment method, and the boots are integrated with hydraulic cylinders, which can easily adjust the foundation flatness.

We are here to help you

You are welcome to : phone call, Message, Wechat, Email& Seaching us, etc.

Email: info@hnjlzk.com

Phone / Whatsapp: +8615936220108

Our professional team will reply you as soon as possible.

Submit Request

PDF Request

Simply fill out the form below and the catalog will be available for download!